Optical Surfaces Ltd reports that it has received a follow-up order from Magdalena Ridge Observatory (MRO) to produce three second generation off-axis beam compressors to expand the capabilities of the facility’s optical interferometer.

“Light painting” of the MROI delay line vacuum pipes. (MROI — Colleen Gino)

The Magdalena Ridge Observatory Interferometer (MROI) project’s mission is to develop a ten-element imaging interferometer to operate at wavelengths between 0.6 and 2.4 microns with baselines from 7.8 to 340 meters. The technical and scientific goals of the interferometer are to produce model-independent images of faint and complex astronomical targets at resolutions over 100 times that of the Hubble Space Telescope.

Dr Michelle Creech Eakman, Professor of Physics at MRO commented “To minimize diffraction effects from long distance propagation, the original 7.5x off-axis beam compressor supplied by Optical Surfaces was designed to allow a 95-mm beam of starlight to be reduced in size for the final division among instruments on the telescope. Because of the excellent performance of this optical system, we decided to single source from Optical Surfaces Ltd for three second-generation beam compressors that offer a better field-of-view to aid interferometric alignment. These beam compressors will be crucial components in the MROI as they will allow us to work in the smaller beam space (less than 20mm diameter) outside the vacuum system. We are hoping to attain first fringes during the first half of 2024”.

Dr Aris Kouris, Sales Director at Optical Surfaces Ltd added “Located at 10,600 ft above sea level in the Magdalena Mountains, our beam compressors for the MROI are subject to considerable variation in temperature. This necessitates that we incorporate invar element tie bars in the beam compressor design to provide thermal stabilization. Our beam compressors incorporate high-precision off-axis mirrors, which provide an unobstructed output and highly efficient transmission. Beam compressors are the optical tool of choice for decreasing the diameter of a collimated input beam to a smaller collimated output beam. The reflective design of our beam reducers is achromatic and with protected silver coatings can operate from the visible spectrum to far IR without adjustment”.

For further information on high precision ellipsoidal mirrors please visit https://www.optisurf.com/index.php/products/conic-sections/ellipsoids/ or contact Optical Surfaces Ltd. on +44-208-668-6126 / [email protected].

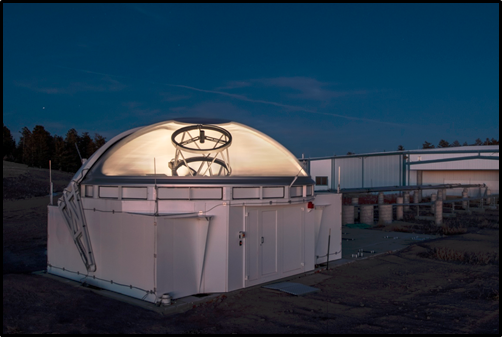

Telescope #1 on the array outside the MROI beam combining facility. (MROI — Colleen Gino)

Optical Surfaces Ltd has been producing demanding optical components, optical systems, and mounts for more than 60 years. The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk. This provides an environment where temperature is naturally thermally stable, and vibration is extremely low. With such stable conditions testing of high precision optical components and mounted mirrors becomes quantifiable and dependable. In addition to these natural advantages, Optical Surfaces has invested in an extensive range of test equipment and have developed methods to ensure accurate and reliable testing.