Encouraging the momentum that is building around the necessity to validate parts made via additive manufacturing (AM), Dimensionics Density is showcasing its automated density determination solution at Formnext 2023 7-10 November in Hall 11 Stand C61.

The technology has been recommended by Fraunhofer IAPT in an independent study for applications where a statement on the density has to be made quickly or frequently, making it a perfect fit for volume production scenarios. In addition, the company’s solution was applauded for simplifying machine approvals, and thus reducing the costs of AM quality assurance.

Philipp Pruesse, Head of Sales at Dimensionics Density, says “With Formnext 2023 just around the corner, we feel as if we are presenting a technology at the show which is absolutely in the sweet spot when it comes to demand from users of AM for production. From time to time, various aspects of the AM process chain come under scrutiny, and at the moment the focus is on technologies that validate the quality of parts made via AM. Now an accepted production technology, ‘near enough’ when it comes to quality is no longer good enough. Today, in busy high volume production settings, users have to be able to validate the quality of AM parts quickly, accurately, and cost-effectively. It is here that we have focused our attention, and we invite attendees to come and see our automatic density determination technology up close and personal at the show.”

The company’s technology resides at the interface between the need for supremely accurate AM part validation technologies, and the need for automation in the AM process chain.

Pruesse continues, “In the dynamic and growing area of AM, automation is the key for scalability, consistency, and economic viability. Unlike traditional manufacturing methods, as we all know, AM allows for intricate designs and bespoke creations, but this can also introduce complexities that demand precise, repeatable actions. Automation seamlessly bridges the gap between intricate design freedom and volume production, ensuring that each part adheres to stringent quality standards while reducing human error. As we envision a future where AM plays a central role in global production, integrating automation becomes imperative. Not only will it bolster production rates and reduce costs, but it will also be a catalyst in unlocking the full potential of AM, fostering an era of manufacturing that is more adaptive, efficient, and innovative than ever before. We are proud to be at the vanguard of this manufacturing revolution.”

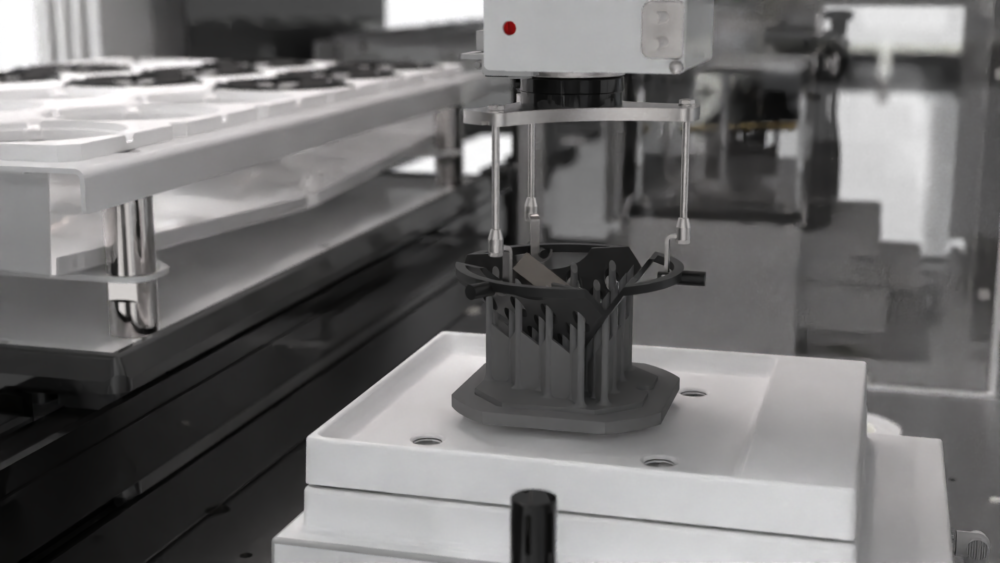

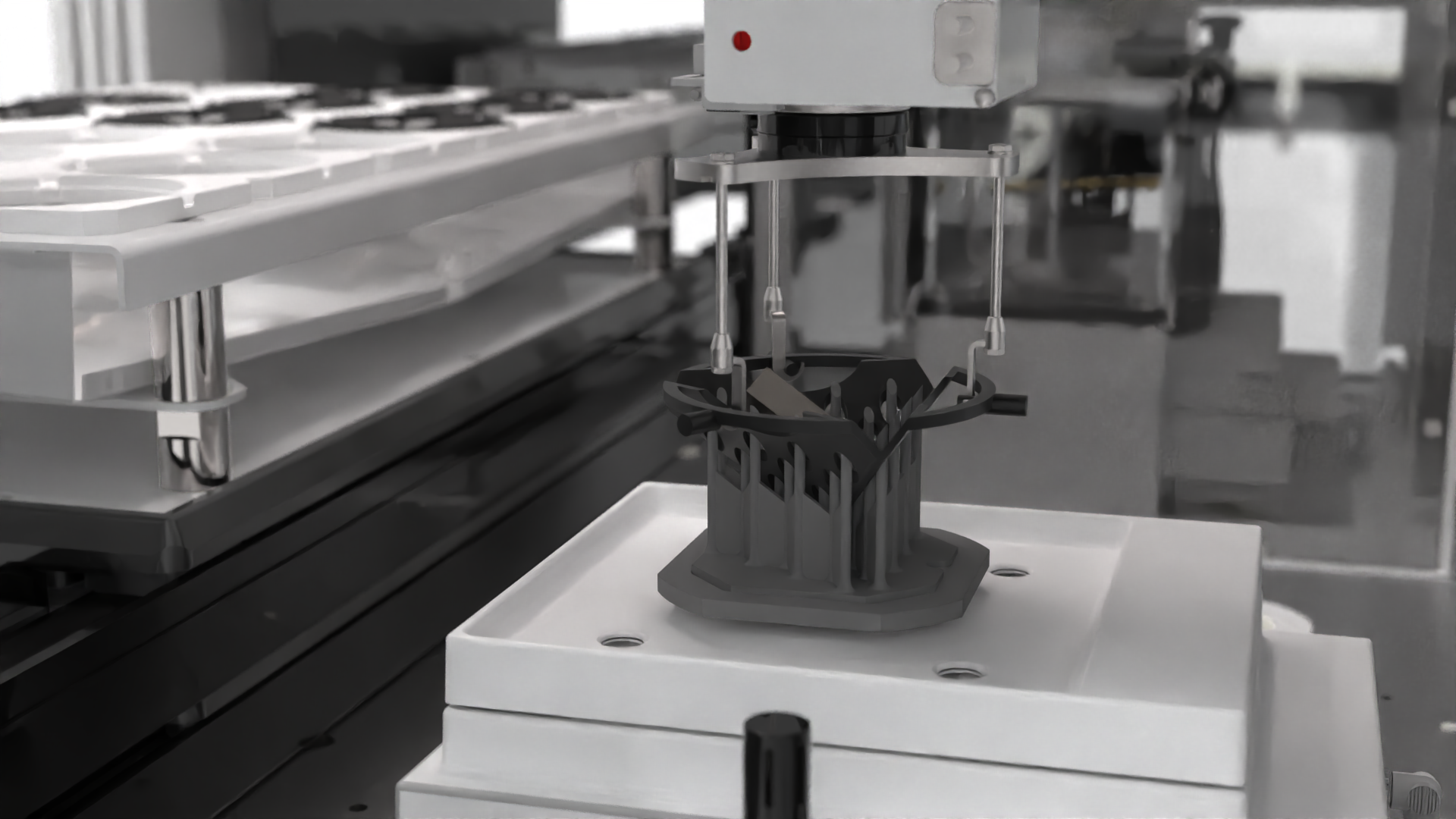

Dimensionics Density’s density determination process uses the time-worn Archimedes principle but in combination with modern automation technology, therefore squeezing every last bit of accuracy out of this method. The samples to be measured are placed in a special component carrier, which is provided with openings on the underside. These component carriers are transported through the system by an axis robot and lowered centrally and precisely onto the scales.

On the scales themselves is a lift-out rack with pins that lifts the component over the openings in the component carrier and thus lifts the component out of the carrier. The automated handling eliminates human influence on the measurement, as the parts are always placed identically onto the scales.

The scales are designed to be insulated from vibration. In addition, all ambient conditions such as temperature, air pressure, and water temperature, are recorded via climate sensors, and their influence on the measurement result is taken into account directly in the evaluation algorithm when determining the density.

Dimensionics Density will be displaying a working machine at Formnext, and invites attendees to come armed with details of real parts and applications which the company will review and feedback on post-show to indicate the usefulness of its technology for AM production scenarios.