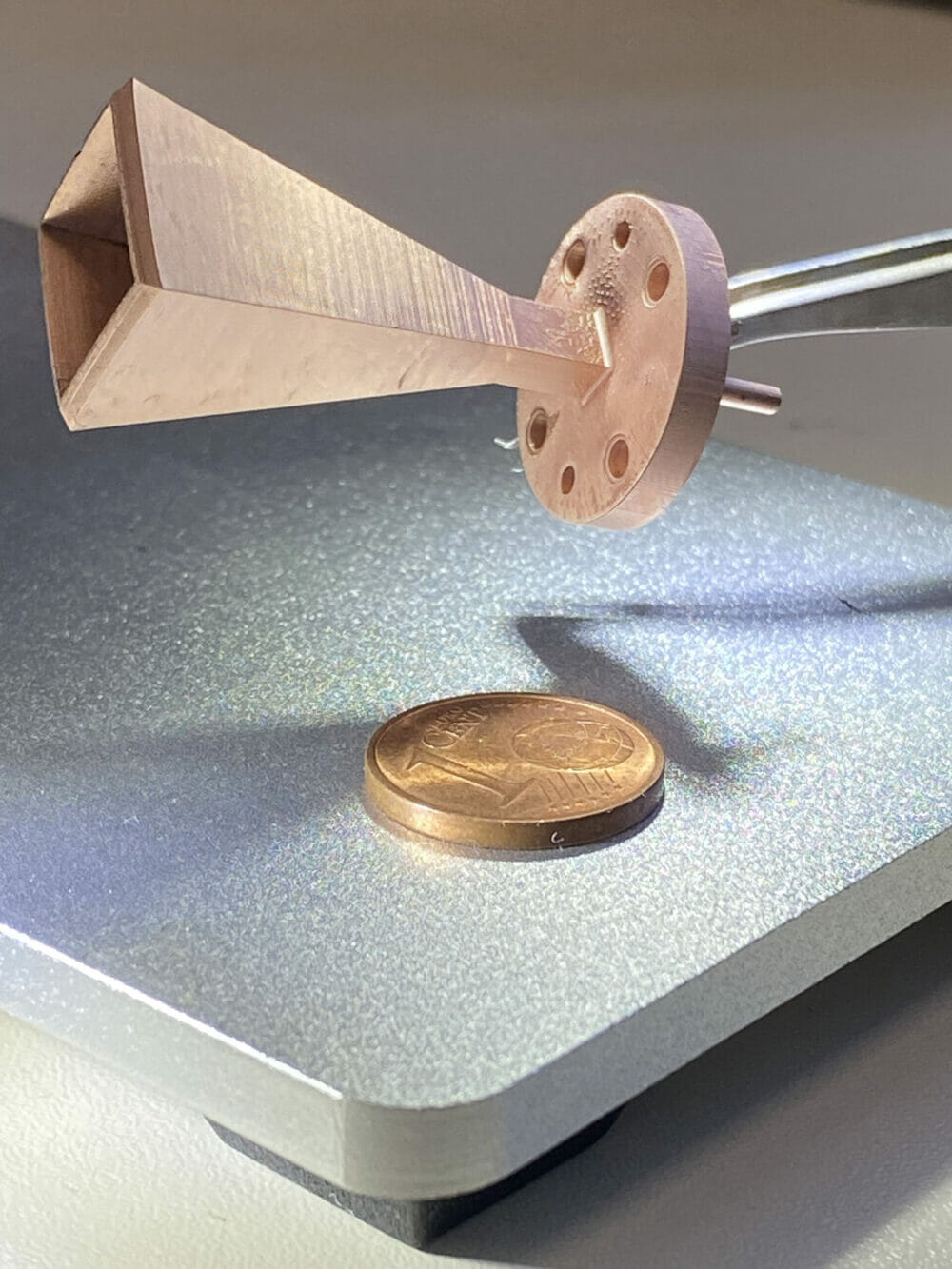

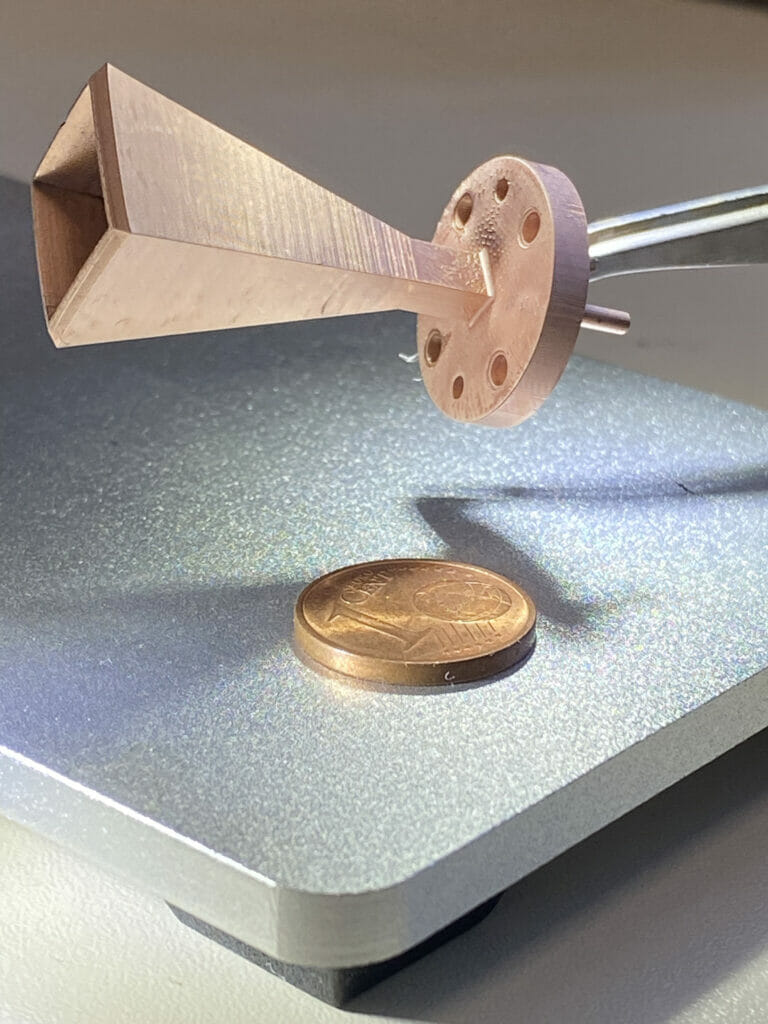

Horizon Microtechnologies provides a suite of in-house coating processes that add material and functionality to a microstructure, all developed to work with a range of materials and shapes. Effectively, the company produces parts using the microstructure as a template, but its coating technologies make the final parts much more functional than the original template in a variety of ways.

Early stage financing recently secured by the company has allowed it to invest in a micro AM platform from leading innovator Boston Microfabrication (BMF). Recently installed, the BMF S240 machine is now up and running in Horizon’s facilities, and the company is now able to produce micro AM templates in house to which it can apply its proprietary environmentally resistant, metallic, or non-metallic conductive coatings.

The S240 builds extremely intricate parts with excellent precision and tolerance attainment, and comes from BMF’s 10μm series of micro AM solutions, an ideal option for Horizon where the requirement is for ultra-high resolution, accuracy, and precision. The S240 can print engineering-grade materials and boasts a large build volume — specifically designed to meet the needs of industrial production.

Andreas Frölich, CEO at Horizon says, “The arrival of the BMF micro-AM machine is a vital step for us as a company. We already provide a suite of post-build coating technologies for micro AM parts to enhance their functionality, but our core know-how goes beyond this, with a unique in-house understanding of overall micro-AM based 3D microfabrication process chains. The introduction of the BMF micro-AM machine at our facilities brings the full technology infrastructure for leveraging this 3D microfabrication know-how on behalf of our customers in-house, which will create the enormous advantage for them of accessing a truly vertically integrated solution partner that can support from design through manufacturing to delivery in a one-stop-shop fashion. It will also speed up R&D and the innovation of our disruptive 3D capable post-build coating technologies for micro-AM parts, allow for a much broader and more agile and timely interaction with customers, and enhancing sales and marketing activities.”

Andreas Frölich, CEO at Horizon says, “The arrival of the BMF micro-AM machine is a vital step for us as a company. We already provide a suite of post-build coating technologies for micro AM parts to enhance their functionality, but our core know-how goes beyond this, with a unique in-house understanding of overall micro-AM based 3D microfabrication process chains. The introduction of the BMF micro-AM machine at our facilities brings the full technology infrastructure for leveraging this 3D microfabrication know-how on behalf of our customers in-house, which will create the enormous advantage for them of accessing a truly vertically integrated solution partner that can support from design through manufacturing to delivery in a one-stop-shop fashion. It will also speed up R&D and the innovation of our disruptive 3D capable post-build coating technologies for micro-AM parts, allow for a much broader and more agile and timely interaction with customers, and enhancing sales and marketing activities.”

While Horizon is positioned to work with customers at various stages in the product development cycle, having the in-house infrastructure to act as an end-to-end product development and contract manufacturing partner means that it is able to influence the design of micro AM parts to optimise them for end-use functionality and for the application of its proprietary coating technologies.

Frölich continues, “When producing exceptionally precise and tight tolerance parts and components, the significance and added value of a vertically integrated development and manufacturing partner becomes paramount. First and foremost, the early inclusion of manufacturability considerations along the full microfabrication process-chain in design decisions reduces the number of iterations during the product development phase. This concurrently reduces the time-to-market and overall product development costs. Furthermore, our high degree of vertical integration entails tight control and coordination over the various stages of production, from raw material sourcing to final assembly. In the context of precision manufacturing, this approach ensures seamless quality control, optimal material selection, streamlined communication, and enhanced process efficiency. Importantly, the interdependencies of the different process steps are established, the manufacturing process’ execution is fully transparent and can be tightly controlled.”

By eliminating dependencies on external vendors, a vertically integrated supplier such as Horizon can guarantee consistency in specifications, minimize lead times, reduce potential bottlenecks, and ultimately deliver highly accurate and reliable components that adhere to the strictest tolerances and specifications.