Colin Spellacy, Head of Sales. Rösler UK / AM Solutions

Additive Manufacturing (AM) has revolutionized the manufacturing industry by enabling the creation of complex and customised parts with unprecedented design freedom. However, one of the challenges associated with AM is the need for post-processing to achieve the desired surface finish and functional properties. While alternative AM post-processing methods have emerged, this article explains how traditional finishing technologies like mass finishing and shot blasting remain an ideal fit for post-processing AM parts in key industry sectors, offering not only superior results but also cost-effectiveness.

AM processes often result in parts with rough surfaces, visible layer lines, and other imperfections that need to be addressed for functional and aesthetic purposes. Post-processing techniques are employed to improve the surface finish, remove support structures, enhance part accuracy, and achieve desired mechanical properties. These processes are crucial for industries such as aerospace, automotive, and medical where high-quality surface finishes and precise geometries are required.

TRADITIONAL FINISHING TECHNOLOGIES

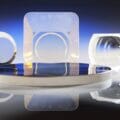

Mass Finishing. Mass finishing is a widely used traditional finishing technology that involves the use of abrasive media, chemicals, and mechanical action to improve the surface finish of parts. In the context of AM post-processing, mass finishing methods such as tumbling and vibratory finishing can effectively remove layer lines, burrs, and surface irregularities, resulting in a smoother finish. The ability to process multiple parts simultaneously in mass finishing machines also enhances productivity and reduces overall processing time.

Shot Blasting. Shot blasting is another well-established finishing technique that utilizes high-velocity projectiles to impact the surface of a part, removing contaminants, burrs, and irregularities. Shot blasting can be particularly effective in post-processing metal AM parts, as it not only improves surface finish but also induces beneficial compressive residual stresses, enhancing part strength and fatigue resistance. Additionally, shot blasting can selectively modify the surface roughness to optimize tribological properties, making it suitable for various applications.

ADVANTAGES OF TRADITIONAL FINISHING TECHNOLOGIES

Compared to alternative AM post-processing methods like chemical vapor smoothing, traditional finishing technologies offer significant cost advantages. Mass finishing and shot blasting equipment is generally more affordable to purchase and maintain, making them accessible to a wide range of manufacturers. Moreover, the consumables used in these processes, such as abrasive media or shot, are relatively inexpensive, resulting in lower operational costs compared to other techniques.

Traditional finishing technologies excel in scalability and throughput. Mass finishing machines can handle large volumes of parts simultaneously, making them highly efficient for batch processing. Similarly, shot blasting equipment can accommodate various part sizes and geometries, enabling high throughput and reducing the time required for post-processing. This scalability is particularly advantageous in industries with high production demands, where alternative methods may struggle to match the pace.

Another key advantage of traditional finishing technologies is their flexibility and versatility. These methods can be applied to a wide range of materials used in AM, including metals, plastics, and ceramics. Different abrasive media and shot materials can be selected based on the specific requirements of the parts, allowing manufacturers to tailor the finishing process to achieve the desired surface characteristics. This adaptability makes traditional finishing technologies suitable for diverse AM applications.

MEETING THE INDUSTRY CHALLENGE

To demonstrate the effectiveness and cost-efficiency of traditional finishing technologies for AM post-processing, an analysis of the requirements of various key industrial sectors can be highlighted. These examples showcase the successful application of mass finishing and shot blasting in industries such as aerospace, automotive, and medical, emphasizing the improved surface finish, enhanced mechanical properties, and cost savings achieved through these methods.

Aerospace

In the aerospace industry, where high-performance and precision components are crucial for safe and efficient flight, the post-processing of AM parts is of utmost importance. Traditional finishing technologies have demonstrated their worth in this sector by effectively addressing the specific challenges associated with aerospace applications.

One significant advantage of mass finishing processes in aerospace post-processing is their ability to refine the surface finish of often hard to process lightweight metal aerospace components. The AM process can introduce surface roughness and irregularities that need to be addressed for optimal performance. Mass finishing techniques, such as tumbling and vibratory finishing, employing abrasive media and mechanical action to reduce roughness, remove burrs, and improve the overall surface quality of metal components.

Additionally, the fatigue resistance of aerospace components is of critical importance, as these parts are subjected to cyclic loading and must withstand rigorous operating conditions. Traditional finishing technologies have been successful in improving the fatigue life of critical aircraft components. Shot blasting, for instance, has been employed to remove support structures from complex geometries, ensuring a clean and uniform surface. This process not only enhances the aesthetic appearance of the part but also induces beneficial compressive residual stresses on the surface. These compressive stresses can counteract the tensile stresses experienced during service, increasing the fatigue strength and extending the component’s operational lifespan. By utilizing shot blasting as a post-processing technique, aerospace manufacturers can optimize the fatigue performance of additively manufactured parts, enhancing their reliability and reducing the risk of failure.

Automotive

Mass finishing, in particular, has played a significant role in improving the surface finish of 3D-printed automotive components, such as intake manifolds and engine parts.

In the automotive sector, where precision and high-performance are essential, the surface finish of AM parts directly impacts their functionality. Mass finishing techniques have proven effective in refining the surface quality of 3D-printed automotive components, reducing roughness and eliminating visible layer lines. By achieving a smoother surface finish, mass finishing processes not only enhance the aesthetic appeal but also contribute to reduced friction and improved performance. For example, in intake manifolds where smooth airflow is crucial for optimal engine performance, the use of mass finishing techniques helps streamline airflow, minimize turbulence, and improve overall combustion efficiency. Additionally, by reducing surface roughness, mass finishing enhances the wear resistance of automotive parts, resulting in increased durability and longevity.

Shot blasting is also used to remove residual powder from 3D-printed parts, ensuring their cleanliness and preparing them for subsequent coatings or treatments. The removal of residual powder is critical as it can negatively impact the part’s surface integrity, structural strength, and functional properties. By effectively removing powder particles, shot blasting improves the overall cleanliness of the components, creating a suitable surface for coatings or treatments like painting, plating, or adhesion of functional materials. This enables automotive manufacturers to achieve the desired aesthetic appearance and enhance corrosion resistance or other functional attributes of the finished parts.

Medical

In the medical industry, precision, cleanliness, and biocompatibility are critical factors, and traditional finishing technologies have demonstrated their value in post-processing AM medical devices and implants. The use of mass finishing and shot blasting techniques has proven effective in meeting the stringent requirements of the medical sector.

The surface finish of medical implants plays a crucial role in their performance and biocompatibility. Mass finishing processes are successfully employed to refine the surface of 3D-printed medical implants, reducing surface roughness and eliminating imperfections. By achieving a smooth and optimised surface finish, mass finishing methods minimize the risk of bacterial adhesion and biofilm formation, which is critical for reducing the risk of infections associated with medical implants.

In addition to surface finish, cleanliness is of utmost importance in the medical industry. Traditional finishing technologies, such as shot blasting, are utilized to ensure the cleanliness of medical devices and remove residual powder resulting from the AM process. Shot blasting ensures a clean and sterile surface. This cleanliness is crucial for medical devices that require subsequent sterilisation processes. The removal of residual powder through shot blasting enhances the sterilisation properties of medical devices, enabling more effective and reliable sterilization procedures. This is especially important for implants that need to be biocompatible and safe for use within the human body.

CONCLUSION

Mass finishing and shot blasting offer numerous advantages when it comes to post-processing AM parts. They not only provide superior surface finishes but also demonstrate cost-effectiveness compared to alternative AM post-processing methods. The scalability, throughput, flexibility, and versatility of these techniques make them an ideal fit for a wide range of applications across industries. The showcased industries and real-world examples further strengthen the argument for the utilization of traditional finishing technologies in AM post-processing.

As the AM industry continues to evolve, it is crucial to recognize the value and benefits of traditional finishing technologies. By leveraging these established methods, manufacturers can achieve high-quality surface finishes, improve mechanical properties, and reduce costs in the post-processing of AM parts. Embracing the synergy between traditional finishing technologies and AM will undoubtedly lead to more efficient and cost-effective production processes in the future.

About AM Solutions

Colin Spellacy is the Head of Sales at Rösler / AM Solutions UK. AM Solutions is part of the Rösler Group, which has been a leading expert in the field of surface finishing for more than 80 years, and offers the most extensive portfolio of mass finishing systems, shot blasting, consumables, and services in the world. Renowned companies from a wide range of industrial sectors trust in Rösler products and services. AM Solutions was created from this rich heritage to apply the knowledge and expertise gleaned from 8 decades working in traditional manufacturing processes to the emerging and disruptive area of additive manufacturing. AM Solutions’ specialist team is able to design an AM post processing system that is perfectly suited to specific applications.