~A call for a better screening in pellet and powder production and how businesses can succeed~

Poor raw powder and pellet material quality can create high wastage in production processes, despite effective equipment being available to resolve them. Here, Stephen Harding, industrial vibratory sieves specialist and managing director of Gough Engineering, urges businesses to invest in better screening equipment for powders, pellets, plastics and other irregular granulated products.

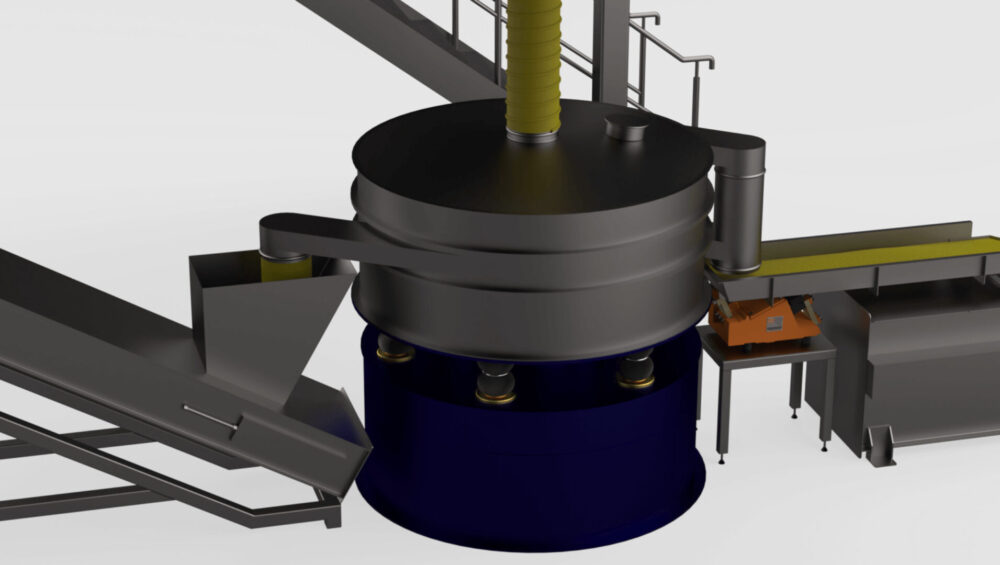

Businesses in the pharmaceutical, food and renewables sector should invest in effective vibratory sieves to improve and secure powder and pellet feed stock quality. Gough Engineering manufactures a range of screening systems and are promoting managers and engineers to trial the Vibrecon® range of vibratory screening equipment.

The Vibrecon® range includes models designed to suit the demands of different industries, such as the Vibrecon® (GVC) PS pellet screener in the sorting of masterbatch pellets during an extrusion process or renewable biofuel pellets. The range also includes the Vibraflo® (GVF) scalping/screening machine, which is particularly suited for higher volumes of screening powders of various kinds.

While the food, pharmaceutical and renewables industries have significantly different production processes, the powdering and pelleting challenges can be the same. These processes require uniformity of size, both for effectiveness and safety. In all sectors, effective quality control of particle or component sizes may be achieved by correctly selecting screening machines. Gough also offer fractional separation by incorporating additional deckware with variable meshes/perforated holes.

Traditionally, misshaped pellets or powder granules may end up trapped in the sieving equipment. This may increase the volume of unnecessary production waste and can lead to blockages that slow the flow of product and can ultimately result in more downtime.

Vibratory sieves can avoid this by using more uniform vibrations to minimise screen blinding. The Vibrecon® range also features a separate exit point in the side for misshapen products to fall through, which engineers can then collect and process again to address the defects. Plants therefore reduce the amount of product waste in their processing lines.

The issue of screen blinding is a significant one for most industries involved in the production of powder products. As powdered materials are processed through sieving equipment, large granules can block holes and gradually reduce throughput. This is particularly problematic for the food industry, where products such as powdered milk often clump during production to create blockages.

Without the use of vibration to adjust the behaviour of the powder flow, mesh blockages accumulate and require maintenance engineers to temporarily disrupt production to clean the screen. Gough Engineering’s vibratory sieves reduce the need for engineer intervention, keeping production running as normal. Any maintenance required is streamlined due to the Vibrecon’s quick release clamps and ease of installation.

Gough Engineering also provides ultrasonic screening equipment that can effectively prevent screen blinding from occurring where very fine powder is being screened. This equipment uses high-frequency vibrations to shake powder during the screening process, significantly reducing the likelihood of powders forming blockages and providing a consistent rate of throughput.

Engineers can also call on the company’s service engineers for maintenance help. Gough Engineering provides sieve maintenance and support service to help with everything from sieve re-meshing to general equipment maintenance as well as providing equipment for hire and demonstration on short production runs.

The Vibrecon® equipment is available in a range of sizes to suit the needs of a variety of production lines. We urge businesses to trial the Vibrecon® to not only see its impact on throughput and quality, but also to determine the best size for their needs.

For more information on Gough Engineering’s range of vibratory sieves, or to arrange a trial of the Vibrecon®, contact the company on +44 (0) 1782 567 777 or visit the website.