The key to determining the true structure and quality of your metal samples is precise and efficient metallographic specimen preparation, which can enhance your hardness testing capability.

Hardness testing plays a critical role in various fields, such as academic research, automotive and aerospace production, and evaluation of coatings and case hardness treatments. Accurately measuring the hardness of materials is necessary to ensure the quality and dependability of final products.

However, selecting a suitable hardness tester from the wide range of options available in the market can be a daunting task. Moreover, the expense of purchasing a hardness tester can exceed the cost of obtaining a complete suite of sample preparation equipment and consumables.

To simplify the process of hardness testing, it is essential to adhere to ISO and ASTM standards for sample hardness calculation and testing unit calibration.

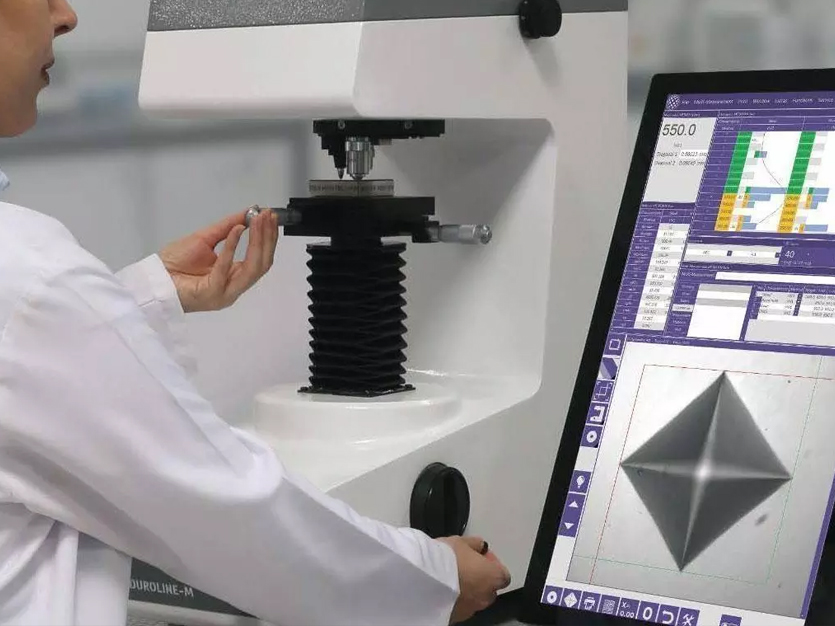

In response to this challenge, Kemet has introduced its Duroline series of benchtop hardness testers. Equipped with an integrated 22″ full HD multi-touch monitor, these testers have the capability to perform Vickers and Knoop measurements. The N-sure software package is user-friendly and includes automated multi-measurement options when paired with the automated x/y stage. The software also offers built-in CHD, EHT, and NHT measurement functions for precise results and can automatically generate test reports.

The Duroline series of hardness testers are suitable for material testing labs and smaller production quality assurance departments. They come in various models that can handle test loads from HV0.01 to HV30, making them ideal for testing small precision parts, thin materials, or wire coatings.

For more information and details, please contact [email protected]