Superfinishing is the process of producing a smooth and reflective surface finish on a workpiece. It is commonly used in the manufacturing industry to improve the performance and longevity of a component.

Achieving a surface finish of Ra value below 0.01µm is a significant challenge and often requires compromise in the traditional superfinishing process. Kemet, a global leader in surface finishing solutions, has developed a new composite plate material called PR3, which promises to deliver a solution to this problem. This article discusses the benefits and applications of Kemet’s new PR3 composite material for superfinishing operations.

The traditional superfinishing process involves two stages: lapping and polishing. Lapping is a process of producing a flat surface with a uniform surface finish by rubbing two surfaces together with an abrasive material. The polishing stage involves using a polishing pad to generate a super finish on the workpiece. While this process is acceptable for many parts, it has a side effect called roll-off. Roll-off occurs when the part sinks into the polishing pad material, resulting in the removal of any sharp edges. This effect becomes more obvious the longer a part is processed on the polishing pad, which is undesirable in many applications.

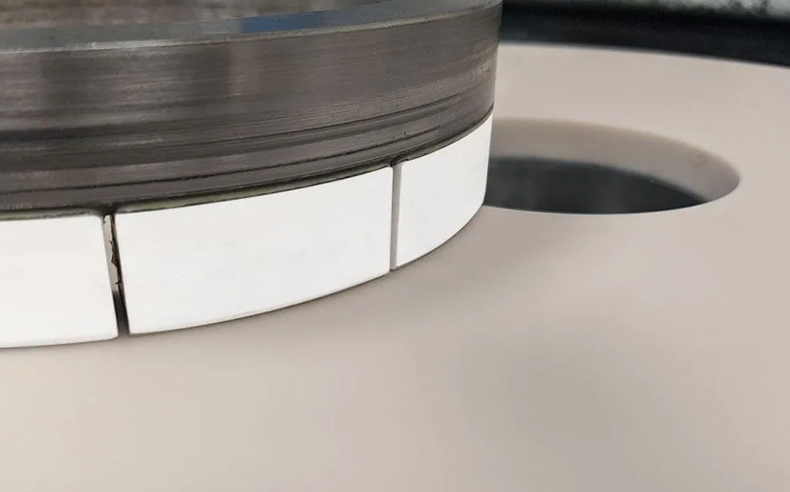

Kemet’s recently developed PR3 composite plate material serves as a pioneering solution to the complications associated with conventional superfinishing procedures. This innovative material has been engineered to complement Kemet’s closely graded Liquid Diamond slurries and Diamond Compounds, resulting in an unparalleled surface finish, surpassing that of standard polishing techniques. Notably, the PR3 composite plate material also boasts material removal capabilities. Its metal-free composition makes it a superior option for applications where metallic contact is undesirable, such as in the nuclear and electronics industries.

Moreover, the absence of metallic components in the plate and the implementation of conditioning rings with ceramic coatings result in a notably enhanced cleanliness of parts after the lapping process, specifically in the case of ceramic materials that utilise white aluminium oxide. Given the superior surface finish that is achieved by the PR3 on numerous materials, it is unnecessary to perform a subsequent pad polishing phase. In situations where a secondary pad polishing procedure is required, the duration of the polishing period is brief enough to prevent any reduction in quality.

The composite plate material, PR3, developed by Kemet, holds exceptional utility in scenarios necessitating the preservation of sharp edges, such as in sealing components, where the occurrence of roll-off would result in leakage. This material is also highly suitable for applications where metallic contact must be avoided, such as in the nuclear and electronics industries. Kemet extends its services by offering free-of-charge testing for all lapping or polishing applications, regardless of the existence of an established process.

For further details, kindly contact [email protected].