~ A story of hydrogen trains, electric dump trucks and renewable backup generators ~

Heavy industry is going green as part of the drive towards net zero. This is being demonstrated by several new developments, including the Alstom Coradia hydrogen-powered passenger train, the Komatsu-Cummins fuel-cell partnership and the Caterpillar renewable energy storage system. Here, Steve Hughes, managing director of REO UK, describes the breakthroughs and explains how these advancements must be tempered by considering their power quality challenges.

Passenger trains going green

Originally revealed in Germany in 2018, the Alstom Coradia iLint is the world’s first 100 per cent hydrogen-powered passenger train, which is already in operation. The train is powered by fuel cells, which convert hydrogen into electricity, producing only water as a by-product. This innovative technology has significant environmental benefits, including zero greenhouse gas (GHG) emissions, and could be a key part of the transition to sustainable transport.

However, hydrogen fuel cell technology presents challenges in terms of electromagnetic compatibility (EMC), which is a critical concern in the design and operation of electric trains. As the fuel cell works, the high-power electrical systems of a train can generate electromagnetic interference (EMI) that can disrupt other electronic equipment or cause radio frequency interference (RFI) with communication systems.

To suppress EMC, a three-phase sinusoidal filter can be used in the power electronics of the train. The filter works by attenuating or suppressing high-frequency components of the current waveform that cause EMI. The filter is designed to smooth out the waveform of the current and voltage signals, making them more sinusoidal.

It achieves this by using inductors and capacitors connected in a specific configuration to form a low-pass filter that blocks or attenuates high-frequency components of the waveform. This ultimately removes unwanted harmonics or noise from the power signal.

Mining machinery going green

Another development in heavy industry going green is the Komatsu-Cummins partnership. This collaboration has resulted in the development of emission-free trucks for mining, which rely on electric and hydrogen fuel cells. These trucks have significant environmental benefits, reducing GHG emissions and improving air quality. They are also much quieter than traditional diesel trucks, reducing noise pollution.

However, the same filtering is required in this mining application to supress electrical interference. One such example is REO UK’s NTT 9339 range of sinus filters, which ensures a clean supply of power to everything from excavators to haulage machines while being designed to withstand ingress from salt, mud and dust.

Backup power going green

Finally, the Caterpillar energy storage system is another example of how heavy industry is going green. This system uses renewable energy sources, like solar power, combined with lithium-ion battery energy storage to provide reliable and sustainable power. The storage system also features a bidirectional inverter, so can be operated as emergency backup power in the event of a power failure. The system is already being used to form microgrids for industrial facilities in remote locations.

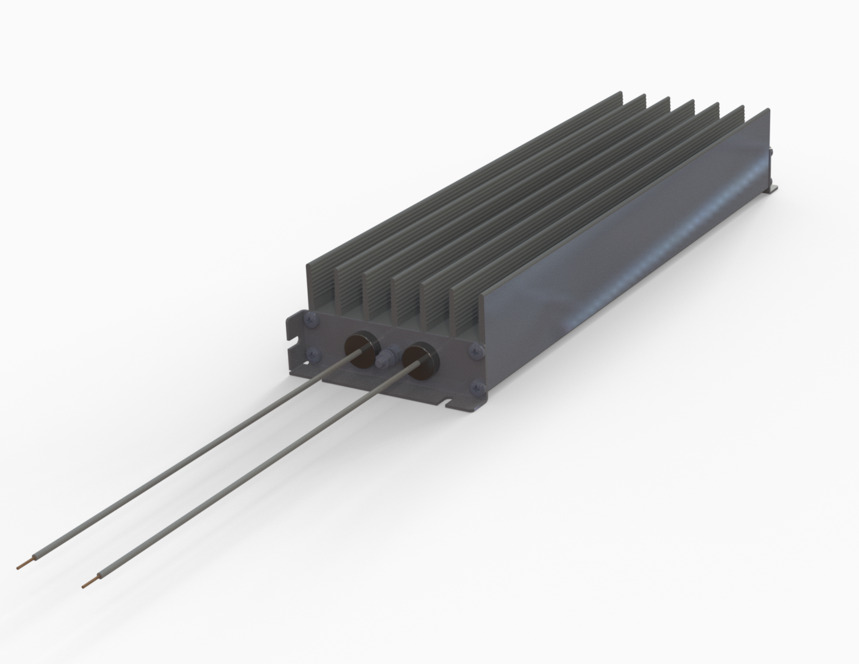

However, energy storage systems like this present challenges in terms of power quality. During periods of overgeneration where there is surplus electricity in the circuit, a braking resistor, such as REO’s BW 156, is commonly used to dissipate the energy by converting it into heat, preventing damage to the system.

As heavy industry goes green as part of the drive towards Net Zero, it’s vital that businesses also embrace clean power-quality, ensuring efficient and reliable operation of their equipment for years to come.

To find out more about REO UK’s range of power quality components, visit www.reo.co.uk