In applications where stiff and robust thin-wall tubes are required, for example for telescoping poles, or camouflage support units, manufacturers have favored metals because of their high stiffness, familiarity, and relatively low price. Traditionally, composites have not been considered to replace metals in these applications because of the belief that glass fiber composites, while lighter, lack the necessary stiffness. Alternatively, carbon fiber composites, while being mechanically suitable, may be considered too expensive. Here Marc Tagher, area sales manager for North America at pultrusion specialist Exel Composites, explains why manufacturers should consider hybrid composites to balance mechanical performance with cost.

Thin-wall composites are normally defined as having a tube wall-thickness between 0.9 mm and 2 mm. These can be used for a variety of applications across many different industry sectors, including camera tripods, window cleaning poles, and military support poles.

Sustainability trends and a need for light-weighting are pushing manufacturers to improve operational efficiencies by reducing weight without sacrificing mechanical properties, which also includes looking at alternative materials. So, how can composites replace metals in these applications, while still maintaining a competitive cost?

Considerations for thin-wall profiles

Stiffness is a key consideration for thin-wall tubes in most applications. Aluminum, which has been the traditional material of choice for many, has a typical stiffness of 70 gigapascals (GPa). In comparison, fiber glass, which is often the first choice for composite solutions because of its relatively low price and lightweight composition, only has a typical stiffness of 40 GPa. Therefore, to match the bending behavior, or el-value, of aluminum, usually thicker tubes are needed, impacting existing design specifications, aesthetics, and weight savings. These are usually manufactured using prepreg processes, where a fibrous material is pre-impregnated with a specific synthetic resin.

Carbon fiber composites tick all the boxes in terms of mechanical properties. They are much lighter than metals and boast much higher stiffnesses, with basic carbon fiber tube having a typical stiffness of 125 GPa and high-modulus carbon fiber tube having stiffness up to 225 GPa. However, carbon fiber composites are also more expensive than metals, which may prevent their use. This is where hybrid composites come in, providing the best of both worlds.

Hybrid composites, a combination of both glass and carbon fibers, allow manufacturers to tailor the mechanical properties for any given application without changing the specified dimensions of the tubes or poles. This is achieved by adjusting the ratio of glass fiber to carbon fiber in the structure.

For example, for window cleaning poles, a customer might require a pole predominantly made from glass fiber for cleaning two-story buildings but need something with a higher ratio of carbon fiber, providing extra stiffness, for poles intended for cleaning five-story buildings. This is a simple task for an experienced composites partner to produce composites tailored for your specific application.

Why choose pull-winding?

The American markets were among the first to fully embrace pultrusion, a continuous manufacturing process Exel Composites is known for. However, the process of pull-winding is relatively new to the area.

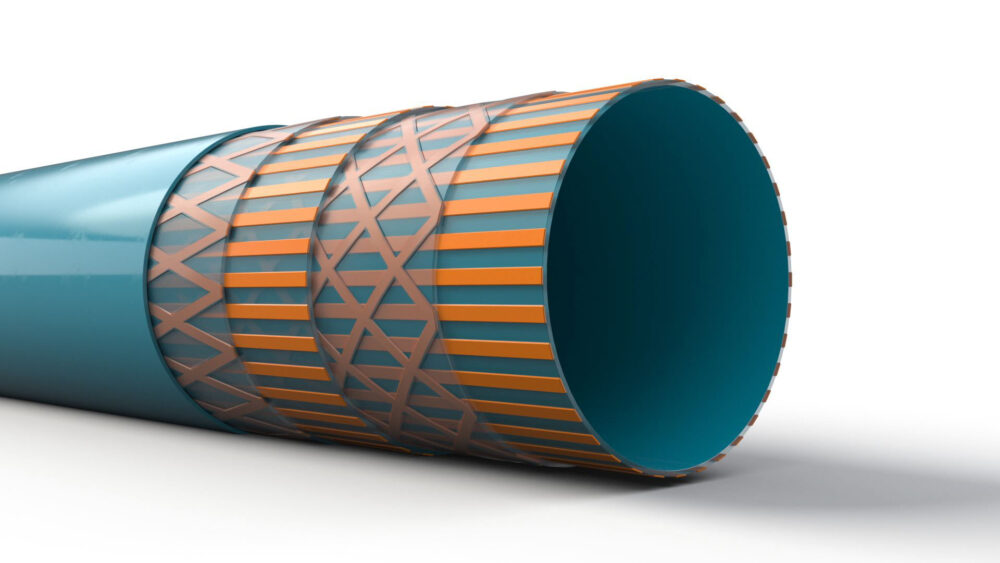

For high volume cost-competitive composite production, pull-winding is advantageous because it ensures consistent high-quality production and high levels of repeatability because of the high level of control in across the single, in-line manufacturing process. Pull-winding is particularly useful for manufacturing hybrid composites because it allows for cross-directional control of mechanical properties (hoop strength) and selective reinforcement of the thin-wall composite tubes.

It does this by combining the unidirectional alignment of fibers with the helical winding of reinforcements, resulting in the ability to control unidirectional fibers and helical winds, from a few degrees up to 90 degrees. These wound transverse fibers give the material more torsional strength, meaning manufacturers can reduce or even replace the reinforcing fabrics and mats used in pultruded composites.

Manufacturing thin-wall composite tubes is possible using other manufacturing techniques, such as filament winding, however these require more manual steps, and are more suited for thick tubes with very large diameters. Furthermore, because they involve more manual steps and smaller manufacturing volumes, it is often the case that thin-wall composite tubes manufactured using filament winding are more expensive. This is because factories must consider things like manual labor costs and longer curing periods.

By working with an experienced and knowledgeable composites partner who understands your application’s requirements and operational challenges, you can ensure you get the optimal solution for any given application. Exel Composites can work with you to develop the optimal hybrid composite for your application, enabling you to cost-efficiently reduce equipment weight without sacrificing mechanical performance.

To learn more about thin-wall composite tubes, visit https://exelcomposites.com/composite-solutions/equipment-and-other-industries/composite-tubes/