Why power protection is a must for industrial SSDs

When power is terminated before a shutdown notification is completed, an “unsafe shutdown occurs,” preventing data in the temporary buffers from being safely flushed onto the nonvolatile NAND. This causes data to be corrupted or lost, and may render the storage device unusable. Examples of unsafe shutdowns include unexpected power outages, accidental removal of the SSD from the computer, unplugging the storage device while power is still on, or battery power loss. Such occurrences can potentially damage a storage device and corrupt data unless there is an effective power loss protection (PLP) mechanism.

SSDs are particularly vulnerable to power-loss events. Unlike HDDs, SSDs do not have mechanical parts, so every component is electronic. The internal data management of an SSD involves many operations that occur in the background, and every power failure can mean undue interruption of those operations, which could affect drive performance. That’s not forgetting system downtime, engineering resource and associated costs for loss of revenue which all could be considerable. So what solutions are on offer in the market?

ATP Introduces MCU-based PLP in Latest NVMe/SATA SSDs

Taiwanese manufacturer ATP electronics has introduced the N600 Series M.2 2280 NVMe and A600 Series Serial ATA (SATA) SSDs, which feature a completely new design of the power loss protection (PLP) array. The PLP utilizes a new power management IC (PMIC) and new firmware-programmable MCU (microcontroller unit). The new MCU design is integrated into ATP’s latest PLP technology, which allows the PLP array to perform intelligently in various temperatures, power glitches and charge states.

In addition to the MCU-based PLP array, the M.2 2280 NVMe N600 Series modules combine the speed and performance of PCIe NVMe with the reliability and endurance features of 3D NAND flash, the high capacity of triple level flash (TLC), high-performance 8-channel controllers, and end-to-end data protection.

So how does the MCU enhance the Power loss protection mechanism?

The MCU intelligently monitors de-glitch power failure conditions and checks the health status of capacitors through the I2C interface, with the Polymer tantalum capacitors providing sufficient sustaining power for data cache flushing, if a surprise power-loss condition occurs.

In addition the microcontroller unit can keep detecting power failure conditions; for example, for a 2.5” SSD, if input voltage drops down to less than 4.0V for several consecutive milliseconds (de-glitch), the MCU will notify the controller to start cache flushing and at the same time, the capacitors will be activated to provide the sustaining power for cache flushing.

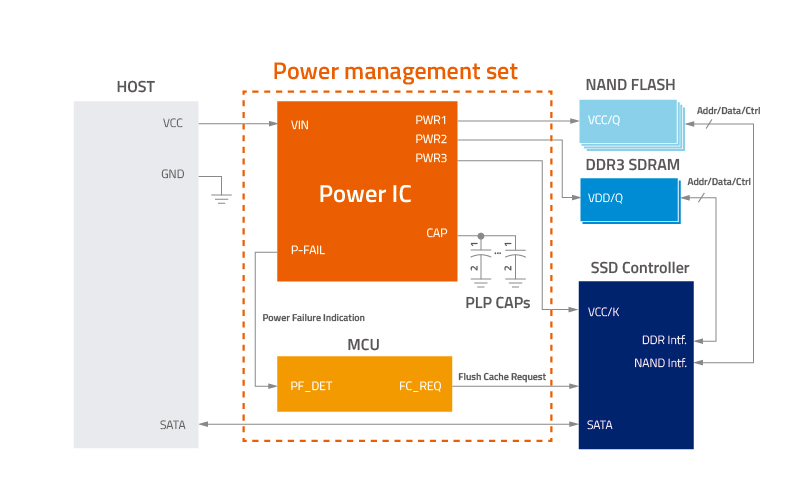

Getting under the cover of the SSDs we can see how this works in the diagram below;

ATP’s new PLP array with PMIC and firmware-programmable MCU

Features and Benefits

Enhanced Device Protection

- Suppression of power-up inrush current according to customer request.

- Input over-voltage protection to prevent damage to the SSD circuitry.

Fast Power On/Off Control

- Cuts the time required from power-off to re-power on the SSD.

Precise Control of Reset Signal Generation and Power Up/Down Sequences

- Prevents potential issues in the power up/down of the SSD.

Customization Options

- The new MCU-based design allows PLP capabilities to be tailor-fitted according to unique customer requirements, application-specific needs, or use cases.

ECC Engine / RAID Support

- Error detection and correction with redundant backup algorithm to eliminate the possibility of uncorrectable errors.

Better Data Integrity

- Input power noise de-glitch to prevent incorrect cache flushing caused by false triggers such as noisy or unstable host input voltage.

- Under-charge/over-charge protection for hold-up power capacitors.

End-to-End Data Path Protection

- Prevents unauthorized access to data while it is being transferred from one storage device to another.

The following table illustrates the advantages of SSDs with MCU-based control compared with SSDs that do not:

| SSDs without MCU | SSDs with MCU |

| PLP capacitors need to discharge/reset before power-on | Immediate power-on initiated regardless of residual voltage on PLP capacitors |

| If power-off state is extremely short: PLP might discharge incompletelyController reset might failSSD might not be recognized and will not be able to reboot | If the power-off state is extremely short: No need for the PLP to discharge completelyMCU resets the controllerSSD can be recognized and will reboot correctly |

SSD power on-off with/without MCU

To sum up The new MCU-based design combines hardware and firmware solutions that safeguard data as well as the storage device for higher levels of integrity and reliability. ATP SSDs with MCU -based PLP include mSATA, 2.5” SSDs, M.2 2242/2280 and NVMe modules with both I-Temp and C-Temp support. ATP’s industrial memory and storage solutions undergo stringent testing and validation to meet the high-reliability, high-performance and high-endurance requirements of mission-critical applications to deliver the best total cost of ownership (TCO) value.

For more information on ATP’s MCU-based industrial flash storage products, contact Simms International.