~ AI and robotics required to tackle climate change ~

According to a study published in Nature, AI could help achieve 79 per cent of the Sustainable Development Goals (SDGs). Such technology could become a key tool for future of our planet, starting by coming out of climate emergency declaration. Here, Neil Ballinger, head of EMEA at industrial parts supplier EU Automation, explains why AI should go hand in hand with robotics to achieve sustainable manufacturing.

In short, sustainable manufacturing decreases waste and reduces the environmental impact of production. Through the creation of energy- and money-saving processes, it is designed to minimise a business’ carbon footprint, while simultaneously conserving energy and natural resources. Sustainable manufacturing can also increase the safety of employees, the community and products.

In 1987, the United Nations Brundtland Commission defined sustainability as “meeting the needs of the present without compromising the ability of future generations to meet their own needs.” Ultimately, this means that wasteful practices must be avoided for the sake of future generations, because if we over-consume resources, they will inherit a world that would not be reversible.

Today, there are almost 140 developing countries in the world seeking ways of meeting their development needs. However, their process of industrialisation and digitalisation should go hand in hand with efforts to ensure significant action against climate change is taken — and that includes the adoption of robotics and AI in manufacturing processes.

The misconceptions

According to the International Federation of Robotics (IFR), the average robot density in the manufacturing industry hit a new global record of 113 units per 10,000 employees, with Western Europe (225 units) and the Nordic European countries (204 units) having the most automated production.

It is frequently said that robots will consume more energy than completing the same process manually. While this might be true, the hourly cost of a robot is basically the cost of energy it consumes, which is typically just over 50p per hour. To put this into perspective, this is about 50 times cheaper than the cost of a manual labour in developed countries.

Moreover, robots can also save energy by ensuring a fully automated factory can manufacture with the lights out. In this way, a lot of lighting energy is saved since robots do not require bright lighting to perform tasks. Currently, very few factories run exclusively lights-out. However, the availability and accessibility of industrial robots is allowing more and more manufacturing plants to add lights-out shifts to their regular ones, typically at night and at weekends.

Thanks to new machine-as-a-service subscription models, companies of any size and budget can now afford to automate their projects. In this business system, manufacturers can rent robots by the hour and only pay for the time they work, maximising profitability while minimising capital investment.

Yet, factories that can function without human supervision are still rare. Make no mistake ― highly skilled humans are still part of the process. This simply means there are no low-skilled jobs in lights-out factories.

State-of-the-art technology will always require humans to oversee it, removing the notion that robots displace human workers. In fact, research by the International Federation of Robotics (IFR) revealed that between four and six million direct jobs were created around the world because of an increased use of robots.

Hand in hand with robotics

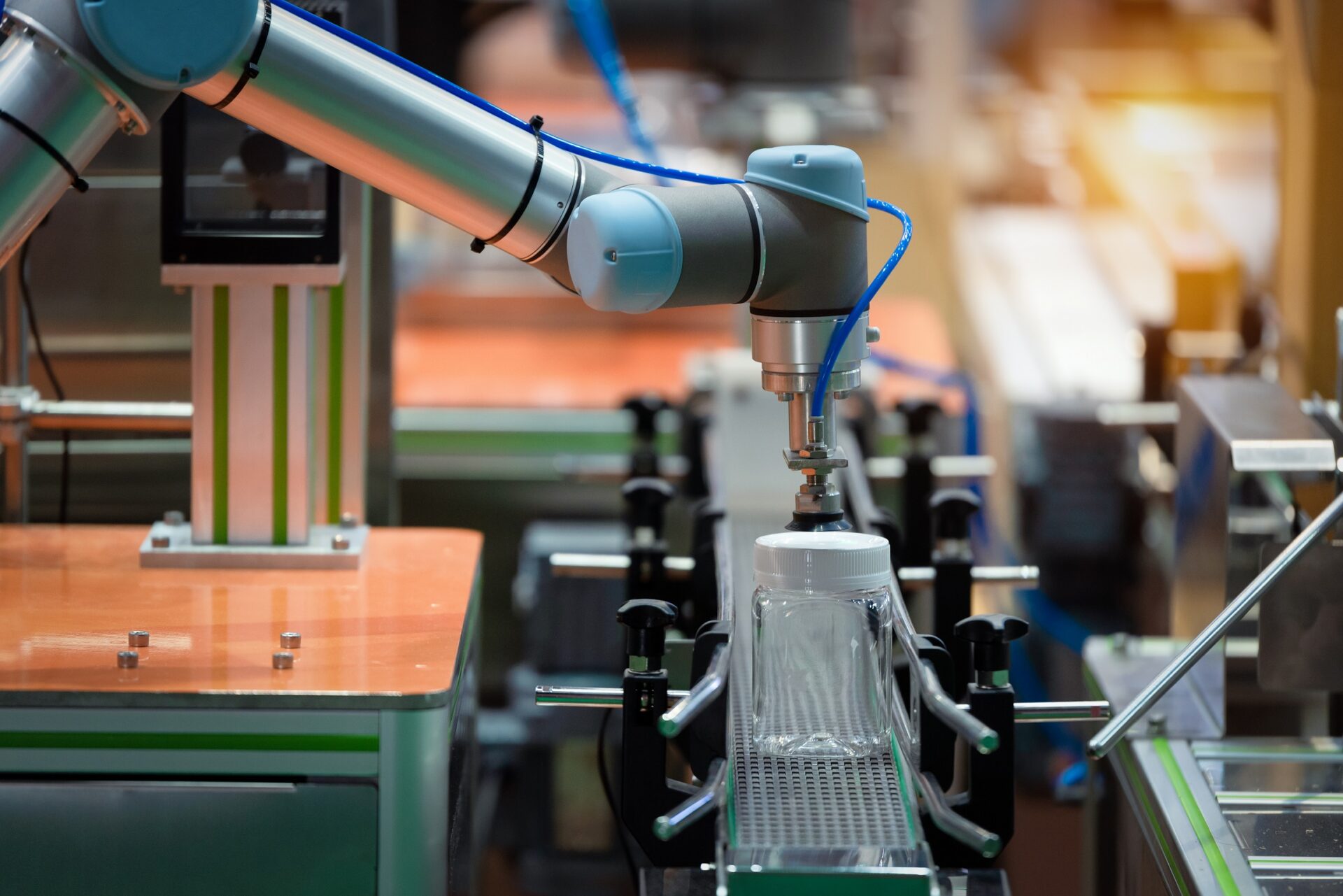

In a joint effort to achieve sustainable manufacturing, AI and robots can help businesses reduce waste and energy use in their production environments. Although robotics can enable better accuracy, AI can design more efficient systems.

And by combining several types of AI, such as machine learning, natural language processing (NLP) and computer vision, plant managers can develop more efficient processes that reduce energy use. What’s more, AI can remove unnecessary steps from the current process by re-engineering processes.

Let’s use facilities management as an example. AI can help reuse heat within buildings and minimise heating and cooling losses. The technology can also be used to regulate lighting and energy needs in buildings by tracking the number of people in a room. For instance, AI can support low-carbon energy systems by integrating renewable energy and energy efficiency, both of which are critical for fighting climate change.

In the next 20 years, we can expect digital technologies such as robotics and AI to enhance the business operation in the manufacturing industry. Supplying to the many companies engaged in a digital transformation, industrial parts supplier EU Automation, realises the role of AI in various sectors.

AI and robotics can help businesses automate their real-time operations, which can improve the sustainability of their processes. More importantly, though, such technology can become a key tool for the future of our planet by helping to achieve sustainable manufacturing.

EU Automation recommends forging relationships with reliable spares suppliers. For more information on its range of automation components to support the sustainable surge, or to help you source parts, visit the website at www.euautomation.com/uk.